The tyres on my Leyland DAF t244 were almost 30 years old. Chances are they were original to the vehicle, which has done hardly any miles (just ticked over 30000 km recently). Tyres that old worry me though, rubber doesn’t last forever. I had a blowout once with my 127, it’s not an experience I would like to repeat.

The stock t244 tyres are 12r20 Goodyear G188. These are imperial tyres – 20inch rims, with a tyre profile nominally 12″ wide and 12″ tall. In reality they measure up at 11.5″ wide at the widest part of the carcass, 9″ wide on the tread:

I was on the lookout for some new rubber, but new tyres are knocking on for £1000 EACH. Spicy!

An ad showed up locally for a set of five brand new Michelin XZLs in 395/85 r20 flavour. They had been in stock as spares for a local company that runs Unimogs, but they had changed to using a smaller 365/85 tyre across their range so these were surplus. XZL’s are my fave land rover tyre, so I couldn’t say no!

When I compared one to the spare from the t244, it was obvious that while the diameter was just a smidge bigger than the stock tyres, the extra width was likely to be problematic. The 395/85 measures in almost bang on at 395mm wide at the tread, vs 9″ (230mm) for the 12r20.

Seeing them side by side brought up a question which, it turns out, is a bit of a sore point (to say the least) on the t244 groups – can I run bigger tyres on the stock 8″ wide t244 rims?

First port of call was the Michelin website, to see what the recommended rim size is for a 395/85 r20 tyre…

…which told me something I didn’t really want to hear – a 10″ rim is required.

…which told me something I didn’t really want to hear – a 10″ rim is required.

This information was mirrored in the ETRTO standards manual:

But, but… What if Michelin were just playing it safe with the 10″ rim requirement, in order to match the ETRTO recommendation (says he, clutching at straws)? I mean at least one person that I know of runs 8″ rims with this tyre, so maybe it’s ok?

To find out if that’s the case, I submitted a query to Michelin. I got a call back a few weeks later from one of their technical guys, who explained that an 8″ rim would be a bad idea for these tyres. Apparently the extra rotation of the sidewall caused by pinching the tyres in to fit an 8″ rim would greatly increase stress in the sidewalls. This is already the highest-stressed part of the tyre, so this additional stress would be reducing the design margin of the tyre. While it might work fine, for a time, a reduction in safety margin might ultimately lead to premature failure of the tyre.

With that information on board, I wasn’t prepared to fit the tyres to an 8″ rim. Much as I like saving money, I also like avoiding tyre blowouts.

So that left me with a decision – sell the tyres, or get some new rims to suit. Weighing up the costs, it would be roughly the same to buy new rims or to sell the 395’s and buy new (12r20) tyres. The added benefit of larger rolling diameter and footprint for the 395/85 r20’s swayed it for me, so I opted to get some new rims.

Nobody makes 10″ rims to suit the DAF, so I had to have some custom ones made to suit. So much for the budget tyre replacement :'(

After getting a few quotes, I opted for a set of 5 20×10 rims from Aspect commercials. They built them to my spec, with a split tubeless rim and the offset (plus PCD, bore etc) that I specified. I wanted the split rim to make DIY tyre changes possible – handy both at home in the workshop and out on the road.

I defined the offset so that the rim centreline was around 10mm further from the centre of the vehicle than with the stock rims. This was to keep the load on the wheel bearings similar, but to give clearance between the rim and the front brake actuators. As the new rims are 2″ wider than stock, this has the effect of moving the outer rim edge out by 35mm, the inner rim edge in by 15mm.

These dimensions are now held by Aspect, so if you want to buy a set of rims to the same spec the part number is 2010/132.

This is the sketch they used to spec the rims, my markups in red (the actual drawing was for an example they sent me for a different lorry).

A few weeks after order, these showed up:

In the spirit of not hiding how much t244 parts cost, they set me back just shy of £3k 🙁

Once I’d stopped crying about the price, I gave them a quick skoosh of paint to match the cab.

The split tubeless rims made fitting the tyres an absolute breeze. With the rim up on blocks I just* dropped the tyre on:

*lifting them wasn’t that easy to be fair, they’re hefty lumps. Just as well I’m super strong…

…fitted the seal ring and outer part of the rim:

…then fitted the lock ring. The lock rings have pegs sticking out, so I made a sort of scissor tool out of some small box section to help fit them. This is much quicker/easier than the lock rings on the stock rims, and there was no fannying about with a tube as these are tubeless.

Then it was just a case of setting up the tyre inflator and retreating to a safe distance while they filled up with air. I put a shed, a lorry, and a house between me and the inflating tyres. Can’t be too careful 😀

Here’s how they looked once inflated, next to a stock wheel/tyre:

Next job was to test fit them.

The front tyres interfered with the brake lines:

I fixed this by adding some 90 degree elbows to the lines to move them out of the way. These are standard 1/4″-18 NPT elbows, available from any hydraulics shop.

These are air brakes, so it was a nice easy swap – just needed some sealing compound and the new parts – no fluid, no mess.

With that sorted, the wheels all fitted no problem.

Some articulation testing showed that at full compression nothing fouled the tyres:

The steps come pretty close when the cab is tilted, but there’s enough space. If there wasn’t, I could flip the steps around as I’m running them back to front – I find the steps are in a more sensible location when you’re getting out of the cab mounted this way around.

Because of the extra width and reduced offset, they do stick out a bit further than the stock tyres. The tread of the fronts are *just* in line with the outer edge of the wings.

They’re legal, but not ideal – they’ll probably cover the side of the lorry in mud. I’ve bought a spare set of wings to widen to suit, I’ve only just had these ones galvanised so don’t want to hack them up.

The rears stuck out well past the the sides of the box.

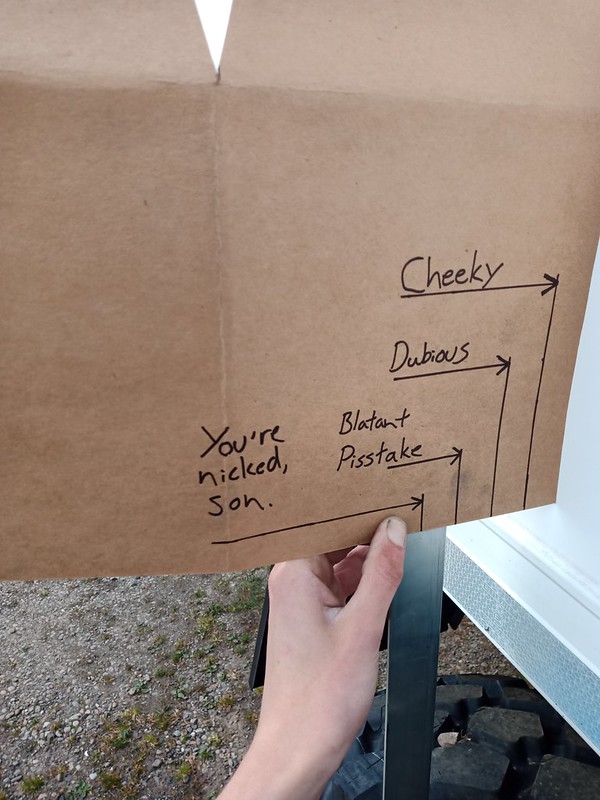

I consulted my tyre protrusion gauge and decided I should make some aluminium arch extensions.

I also had to make a new spare tyre cradle (with longer studs), plus some aluminium spacers, to make room for the wider spare.

So that’s about it – they seem to work nicely, though I’ve not driven them far thanks to Covid-19. They should have done several thousand miles by now if our Balkans trips hadn’t been canned (thanks again, Coronavirus).

Road manners seem fine, there’s a slight increase in road noise, but it’s not intrusive at all. I haven’t done enough miles yet to see what change it has made to efficiency.

I’ve not had them off road yet (unless you count a test drive around the field).

Aired down, they’re going to have a substantially bigger footprint than the stock tyres. The tread pattern is more aggressive too, so it’ll be interesting to see how they work off road. The stock tyres are terrible in mud, so these would have to be truly horrific to be any worse.

The speedo now reads pretty much bang on (vs GPS reading), so it must have been a bit optimistic on the stock tyres.

Oh the Joy’s of having a workshop of one’s own!

Looks nice, a worthwhile mod I’d say.

Thanks for a great written piece . I have put an inquiry into Aspect for some new wheels .

Will jones

Thanks, glad it was of use to you. Now then, just need to give Aspect a call about my commission 😀

Best invest in a pack of Panama cigars Andy !

(or should we call you Carlos Fandango )

https://www.youtube.com/watch?v=xX__PlOda0E